Any vehicle requires optimized tire pressure to operate to its fullest potential. But agricultural equipment, including tractors, have specific tire pressure requirements that make them unique and more valuable. This makes monitoring the tire pressure of your agricultural vehicles even more important.

As little as 10% too little or too much tire pressure can have huge effects on the efficacy and life of your agricultural tires. Proper tire inflation has been found to increase pull by 25% and improve yields – and that’s just the start.

Increasing pull and yield is just the beginning of the benefits of maintaining appropriate tire pressure in your agricultural equipment. The advantages to your agricultural tires include:

And the benefits don’t stop there. It’s not just about your tires, but tire pressure can positively improve your overall impact and lower costs. Proper tire pressure can mean you have a more comfortable ride, optimal footprint and traction, and perfect soil compaction.

Several factors can contribute to tire pressure changes. Simple weather conditions and change of seasons can alter tire pressure. Constant variations in weight or load of the equipment, or just the type of tractor may mean you need to manage to a different psi. And due to the workload and environment, tractor tires naturally tend to leak air over time. All of these reasons make it worthwhile to invest in getting the most out of your tires by optimizing the tire pressure in your agricultural equipment.

The good news is that there are simple solutions to assure you’re getting the most out of your tires – and your equipment– this season.

Doran 360AG™ TPMS is easy to use with its in-cab display and Smart-Link™ Technology, making monitoring the tire pressures on your implements easier than ever – saving you time and money. Read more about preparing your tires for spring planting here.

The best time to install Doran360AG™ TPMS is now – so you are fully prepared for spring planting. We’d love to partner with you in making 2023 your most profitable season yet. Get in touch with us today to learn more.

The immense cost of equipment downtime in the mining industry means that maintaining your machines is crucial for success. Depending on the product, just one hour of downtime for a dump truck can easily cost more than $1000. And that’s assuming that the dump truck isn’t creating a bottleneck impacting other equipment and processes.

Here are some industry best practices for maximizing uptime in your mining operation.

Proactively maintaining your machine’s engine and systems at routine intervals and utilizing scheduled downtime to do so means that your equipment will be up and running when it needs to be. Routine maintenance includes such items as:

When the cost of just one hour of downtime is so high, an investment in on-site maintenance can save a lot of money, particularly when the site is in a hard-to-reach location. Whether hiring a maintenance staff in-house or outsourcing to an expert maintenance company, having a team on-site to maintain vehicles and address unforeseen issues will help maximize uptime by both cutting out transportation time, and is integrated with your process and having in-depth knowledge of your equipment and mining conditions.

Training operators and on-site maintenance staff to listen for feedback from your equipment will help them identify issues sooner. Listening to your equipment will often tell you what needs to be fixed, and allow your team to more quickly perform root cause analysis of issues. Some sounds to listen for include:

Maintaining collaborative relationships with your dealers and distributors can benefit both parties by ensuring that mutually beneficial contracts are in place. For example, having a close relationship with your dealers means having knowledgeable support for equipment, a quick turnaround on replacement parts, and an optimal contract for service. Depending on your operation, this could mean on-site maintenance support, pay-per-service, or cost-per-hour contracts.

Tracking key indicators of vehicle performance can maximize uptime and prolong the life and efficiency of your equipment. There are a few systems that should be closely monitored and tracked.

Tracking fuel usage over time and corresponding hourly usage rates is a key indicator of engine health and performance. It can also help you identify and correct issues early.

Similarly, tracking coolant pressure and temperature can be a key indicator of engine health, and taking care of any issues will prolong engine life and reduce downtime related to breakdowns.

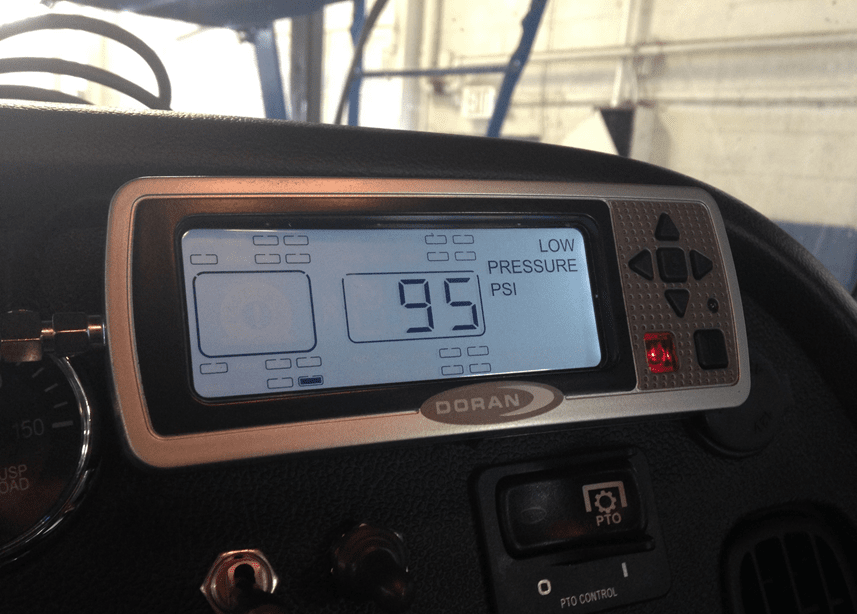

Monitoring tire pressure with the Doran 3600TR(™) Tire Pressure Monitoring System will reduce the risk of long downtime events such as blowouts, as well as generally help your vehicles last longer and drive smoother.

Doran 3600TR(™) TPMS is easy to use with its in-cab display, making monitoring a breeze. Give us a call or send us a message – we'll provide a solution to decrease downtime and make your equipment more profitable year after year.

Fuel efficiency is always a priority but record high fuel costs and trucking demand means it's even more imperative to keep your fleet on the road – as efficiently as possible. Running a fuel-efficient fleet means maximizing output and adding dollars to your bottom line. Here are 5 actions you can take to maintain your fleet's fuel efficiency.

Driver behaviors are core to driving efficiency, and simple reminders for your drivers will help them maximize their efforts. A few ways your drivers can contribute to fuel efficiency are:

Staying on top of preventative maintenance will extend the life of your truck and tires, and improve fuel efficiency. Regularly checking and changing air filters and oil ensures that engines run smoothly. Using the proper oil can improve gas mileage by up to 2%. Tire maintenance including alignment, tread, and pressure safeguard against accidents and keep you on the road longer – but the benefits don’t stop there, balanced tires means your trucks are running more efficiently. A Doran 360™ tire monitoring system can help you proactively monitor your tires. Even keeping your trucks clean helps them run more smoothly.

Maintaining proper tire alignment improves fuel efficiency by allowing tires to roll freely, increasing fuel economy by over $0.30 per gallon. Balanced tires also ensure an even tread – another facet of tire care that leads to efficiency.

Knowing when it’s time to re-tread or replace tires to maintain performance also maximizes fuel efficiency. Substandard tire tread leads to more drag and lower mileage per gallon. A Doran 360™ tire monitoring system can help optimize tire tread and balance.

Tactics already mentioned support aerodynamics for your trailers, such as optimal tire tread and keeping your trucks clean. As you know, too much skin friction, or friction drag, will lead to lower fuel economy. Reducing drag has long been a hot topic in the industry and there have been several technical innovations to reduce the role drag plays in fuel efficiency, including:

Proper tire inflation pressure is paramount to minimizing drag. Low pressure means more friction with the road and lower gas mileage. Doran 360™ TPMS alerts you of tire pressure issues in real-time, so your drivers can correct it immediately and get back on the road.

Not only does proper tire inflation reduce drag, but it also aids in maintaining consistent speeds and improves tread life – enabling some of the key tactics we’ve already covered. It is estimated that low pressure can reduce fuel efficiency by up to 3%. You can further optimize your tire pressure – and fuel efficiency -- with Doran 360™ TPMS. With tire inflation monitoring your drivers can eliminate manually checking tire pressures before each trip, saving them an average of 15-20 mins during their pre-trip inspection.

Effective maintenance, monitoring, and driving habits will improve fuel efficiency and save your fleet time and money. Doran 360™ TPMS will double down on your fuel efficiency with its simple in-cab display that provides real-time communication of tire pressure and temperature issues.

Doran 360™ TPMS is quick and easy to install, so you can get started improving fuel efficiency today. Give us a call or send us a message, and tell us about the issues facing your fleet. We'll provide a solution to increase efficiency and make your fleet more profitable year after year.

INFOREQUEST@DORANMFG.COM 866-816-7233

The off-season for farmers is often spent bookkeeping and repairing equipment to better prepare for planting season in the spring. A huge part of this off-season maintenance is ensuring that your tires are prepared for the upcoming season and are outfitted with the best equipment in order to maintain maximum efficiency.

Recently, we sat down and discussed our tire monitoring system with AG Tire Talk for their fall podcast series, “Driving Yield Thru Tire Technology”. Our tire monitoring system helps farmers improve yields, increase productivity, and lower costs through one simple-to-install system.

Here are some of the highlights of Doran 360AG™ TPMS discussed with Ag Tire Talk, as well as some of the ways the tire monitoring system can benefit you and improve your yields in 2023.

Doran 360AG™ TPMS is incredibly simple to install and easy to use. It is specifically engineered for Ag equipment and is easily maintained and serviced in the field. Wireless tire pressure sensors are available for tires with standard-size valve stems or large bore valve stems and can be used on all types of agriculture equipment including tractors, combines, and when connected, tires for grain carts, slurry tanks, manure spreaders, and tillage implements.

Doran 360AGTM wireless tire pressure sensors are valve-stem mounted, meaning that it is installed by simply unscrewing the valve cap of the tire and placing the sensor on. Simple programming then takes place to specify tire positions, and there is no dismounting of the tire required. The display is powered by the vehicle and requires either 12 or 24 volts of power from the cab.

Utilizing SmartLink technology, Doran 360AGTM TPMS allows farmers to monitor tractor tires at all times, and when connected, tires for grain carts, slurry tanks, manure spreaders and tillage implements.

The in-cab display features a Green Meens GoodTM LED light indicator light & an interactive screen to see the current tire inflation pressures. Real-time alerts for low-pressure & rapid deflation events are provided visually & audibly thru the in-cab display.

The impact that proper tire inflation pressure has on yields, soil compaction, and areas of spending like fuel and new tires is huge. By utilizing a tire monitoring system on your ag vehicles, you are able to proactively monitor tire inflation pressures helping prolong tire life, reduce soil compaction, and increase yields.

If you install a tire monitoring system in your ag vehicles, you will see a return on investment in less than a year. This rings true for even small producers. The combination of ease of use, installation, and affordability make Doran 360AG™ TPMS a game-changer for any farmer.

We’ve discussed the major components of Doran 360AG™ TPMS and the benefits of tire monitoring systems for agricultural vehicles. The off-season is the best time to get those purchased and installed so you can be knowledgeable and prepared when it comes to planting season in the spring.

Make sure that you are maximizing your vehicle’s efficiency through good tire maintenance. We’d love to partner with you in making 2023 a high-yield year and your most profitable season yet. Get in touch with us today to learn more.

INFOREQUEST@DORANMFG.COM 866-816-7233

During peak holiday months, there is a significant increase in travel, online shipping and return orders. According to a recent FedEx report, consumers spent a total of $204.2 billion online shopping and 47% of consumers used same day or next day delivery for holiday shopping convenience in 2021. On top of that, last year, $120 billion worth of goods were sent back between November and February. This trend continues this year, with online shopping expected to reach $1.1 trillion in 2022.

There is no doubt that the holidays are stressful for everyone, but truckers feel the pressure significantly more. Increased travel and online shopping lead to chaos on the roads. Traffic is at an all-time high and while truck drivers are used to long hours on the road, the increased holiday traffic and time away from their own loved ones can add more stress and worry to the job.

Doran understands that being busy is part of the truck driving job, but we also want drivers to feel the holiday spirit. We've put together five tips to help you feel a little more jolly pulling your sleigh this holiday season.

Let’s face it, the more organized you are, the more seamless your travel will be. Before you head out make sure to plan your travel time. If you have a favorite truck stop, rest area, etc. that brings you joy, make it a point to stop there along your route. Map out rest stops that provide the necessities you need to keep moving, like coffee, showers, and gas. If you find a favorite truck stop that has Wi-Fi, use that time to reach out to friends and family back home with a video call. This can lessen the burden of being miles away during the holidays.

Make sure to know when you should expect to go through a weigh station. Research rush hour for each city you travel through, and make sure you plan your stops and weigh station check-ins around those hours. While your travel won’t be perfect, this can give you a structure to work around and eliminate as many unnecessary interferences as possible.

Being on the road during the holidays is stressful, but it can also be lonely. Family and friends may be home enjoying hot chocolate by a warm fire or attending holiday parties, but that doesn’t mean you can’t bring joy to your travels. Have some fun this season, and decorate your truck! Put a wreath on the back, hang lights around the edges, you can even wear a Santa hat while you’re driving. Use this time to get creative, you may even bring a smile to other drivers!

Properly inflating your tires can greatly reduce the risk of accidents, additional maintenance and downtime during travel. Time spent at rest stops can be minimized with properly inflated tires. Many trucks are already operating with low tire pressure and winter months will affect tire pressure even more. When tires are underinflated, more rubber makes contact with the pavement increasing friction and lowering fuel economy. . Improper tire inflation pressure can also increase wear and tear on your tires, and potentially lead to a blowout.

Before your travel time, make sure to check your tire pressure at the appropriate time, and consider including tire inflation check in your travel planning. To make tire pressure checks more efficient, , consider using a tire pressure monitoring system.

Tire Pressure Monitoring Systems continuously measure tire pressure and temperature while providing drivers and fleets with real-time notifications for low pressure & high temperature events. There are a multitude of benefits from using TPMS including increased safety, decreased downtime, increased fuel efficiency, extended tire life, and decreased maintenance costs.

If you're an owner/operator, consider adding this to your truck if not already installed. If you drive for a fleet, share the benefits of TPMS with your leadership if you haven’t already. Ordering and installing a TPMS now is the best way to assure truck driver, customer, and fleet satisfaction during the holiday season. There are many types of tire monitoring systems available that can accommodate a variety of needs, from small to large bore valves and beyond.

Similar to the truck decorating idea, making a playlist for your travels can help keep your spirits up, eliminate distractions, and keep your mind busy while you’re driving. Throw some holiday tunes on the mix, as well as nostalgic songs, and high energy beats for when you begin to feel tired. You can even include podcasts and audiobooks.

Truck drivers are really underrated elves bringing joy and necessities to people all over the world. Although being on the road can feel lonely at times, truck drivers must continue to support each other. Get creative with decorations, make a fun playlist to share with your fellow drivers, or plan to meet up at a rest stop for a quick meal.

Most of all, whether you already have a reliable TPMS or you’re shopping for a new one, every truck driver deserves to feel safe and remain efficient so they can return to their loved ones and celebrate the holidays too.

INFOREQUEST@DORANMFG.COM 866-816-7233

Doran prioritizes continuing education, especially when it comes to advances in industry technology. Our products offer new features and capabilities for fleets and drivers and we are always looking for opportunities to educate and provide solutions for people all over the world.

One way Doran offers insight and knowledge to the industry is by attending and participating in expos and conventions.

This past month, the Doran team had the pleasure of participating in Expo Transporte in Puebla, Mexico for the first time. The event is an industry showcase where suppliers discuss and promote the latest advances in transportation technology. During the last event, there were 46,831 participants from 30 countries, and this year’s event was expected to exceed those numbers.

Doran attended the event along with our trusted partner, Digital Communication Technologies , who designs, builds, and delivers software, technology, and solutions that can read, connect, and exchange data with other platforms. Lee Demis, our Vice President of Business Development, along with DCT team members, met with fleets from all over the Americas to discuss the many benefits of Doran TPMS and its ability to provide off-vehicle notifications for tire pressure and temperature.

“I am beyond grateful to have attended Expo Transporte with our trusted partners, Digital Communication Technologies. The Doran team strives to get the word out about the benefits of our tire monitoring solutions, and events like this are a perfect opportunity to do so.”

Lee Demis

One of the Doran solutions in which many people inquire when our team is on the road is Doran Connect 360™.

Doran Connect 360™, is created with our partner, Digital Communication Technologies, to create software that offers the ability to provide tire pressure and temperature data in real-time, and provide management teams with actionable insights for planning, decision making, and predictive maintenance.

The Doran Connect 360™ solution includes advanced tracking features, vehicle performance, and real-time pressure and temperature data for every tire on every vehicle in the fleet.

The best time to check tire pressure is before driving your vehicle, first thing in the morning, or if you’ve been on the road, after waiting a few hours until the tires cool down. TPMS is a solid tool that can minimize your stress and maximize your efficiency when it comes to checking tire pressure. Doran 360 ™ TPMS continuously monitors tire pressure and temperature and provides immediate notification for low-pressure, rapid deflation, and high-temperature events.

Doran Connect 360 ™ offers more features than many other tire pressure monitoring systems including:

Doran and our partner, Digital Communication Technologies, work together to provide this solution for drivers and fleets which will lead to less downtime, more business, and more safety.

Every year, Doran looks forward to participating in events just like the one we attended in October. We enjoy connecting with so many people in the transportation industry, and sharing our passion with everyone. This year we had the honor of participating in the following events:

Doran is looking forward to attending our last event before the holiday season, at Bauma 2022 in late October.

Staying up to date with advances in technology will lead your business toward growth. Make sure to subscribe to our newsletter to participate in ongoing learning and to stay up to date on events and tradeshows in your area in which we will be participating!

INFOREQUEST@DORANMFG.COM 866-816-7233

The winter months are upon us, which means it is highly likely that the tire pressure warning light on your vehicle will illuminate soon. The reason for this is because the air within the tire fluctuates with temperature changes. When the weather turns cold, air particles inside the tire condense causing tire pressures to decrease. On the other hand, when temperatures are higher, air particles increase in size and tire inflation pressures increase. TPMS technology can help drivers and fleet owners proactively monitor tire inflation pressures, which can lead to decreased equipment downtime, increased safety, and decreased maintenance and repair costs.

As vehicles move down the road, tire temperatures increase, causing the molecules inside the tire to expand, increasing tire pressure. After the vehicle stops and the tire cools down, tire pressure will drop, resulting in flexing of the sidewall. This leads to internal structural damage. When a tire is not structurally sound, it is not able to properly support the load. Continual flexing can cause damage to the belts inside of the tire and potentially result in a blowout.

Maintaining proper tire pressure can lower yearly tire-related costs by $750 - $1,000 per tractor/trailer combination.

According to the American Trucking Association, improper tire inflation pressures are responsible for about one roadside service call per year per tractor/trailer combination due to weakened and worn tires.

Keeping your tires properly inflated can decrease the amount of time a driver is off the road. Doran TPMS technology can eliminate manual tire pressure checks or extra repair and maintenance time by informing drivers and fleet owners of low air pressure levels or any dramatic temperature changes, so problems can be solved in real time.

Improper tire inflation reduces vehicle handling, increases stopping distances, and can lead to overheated tires and potentially catastrophic tire failure. Being proactive instead of reactive when it comes to tire maintenance will keep your drivers and other travelers safe. Doran 360™ TPMS can help find a solution before the problem exists.

Knowing when to check tire pressure can be tricky. For example, checking your tire pressure immediately after you drive can indicate false results. This is because, as we previously stated, the friction from the road causes tires to heat and tire inflation pressure to increase for a brief period of time.

The best time to check tire pressure is before driving your vehicle, first thing in the morning, or if you’ve been on the road, after waiting a few hours until the tires cool down. TPMS is a solid tool that can minimize your stress and maximize your efficiency when it comes to checking tire pressure. Doran 360 ™ TPMS continuously monitors tire pressure and temperature and provides immediate notification for low pressure, rapid deflation, and high temperature events.

Doran Tire Pressure Monitoring Systems can help lower your tire-related expenses, decrease equipment downtime and keep your drivers safe. For anyone who desires lower costs and more efficient business, utilizing Doran 360™ TPMS technology is highly recommended. Don’t know where to start? No worries, our team of experts is excited to connect with you. Call us whenever you’re ready to learn more!

INFOREQUEST@DORANMFG.COM 866-816-7233

It’s almost harvest season, the time of year where you’ll be reaping the fruits of the past year’s labor. Chances are you’re up for the monumental task of harvesting, but what about your tires? AG tires often face harsh conditions during harvest season. From navigating through mud and uneven terrain to rolling over hard stubble, AG tires can see significant damage to tread rubber

and sidewalls.

Modern advancements in crops such as soybeans and corn have produced a more weather and insect resistant crop, but it has also produced a stalk that is stiffer than in previous years.

Being proactive in seeking ways to avoid stubble damage to AG tires is a viable way to increase crop yield and limit downtime.

Here are three ways to reduce stubble damage:

Investing in products that help reduce stubble damage can save farmers a lot of time and money in the long run. Stalk stompers or stubble stoppers are devices that attach to the bottom of your combine’s head or the front of your tractor to prevent stalks from getting caught in the tire treads and jamming up the tires or causing other damage. When you invest in stalk stompers, you'll notice reduced tire wear, less unexpected repairs or replacements, and an increase in crop yields.

The best part about a solution like this is that it doesn't have to be expensive. With a bit of ingenuity and elbow grease, you can make your own stalk stompers or stubble stoppers. All you need is some stout metal tubing, a few pieces of flat bar stock, and some welding skills.

If you don't have the time or skills to make your own, there are plenty of companies that sell them. A quick Google search will reveal a number of options, so you're sure to find one that fits your needs and budget.

Another way to reduce stubble damage is to use tires that are resistant to it - stubble-resistant tires. These tires are designed with thicker sidewalls and special tread patterns that help them better withstand the impact of stalks. This helps to increase crop yield by reducing the amount of time lost to tire damage.

It's equally essential to select tires best suited for your crops by looking at tire tread and pattern shape:

Quality puncture-resistant tires are an investment, but they're worth it, considering the savings you’ll experience down the road from reduced rates of tire failure and less downtime.

Your AG tire's inflation levels are crucial in reducing stubble damage. With the increase of genetically modified crops, stalks are becoming harder and more dangerous to AG tires. Moreover, AG tires are more sensitive to pressure changes than other tires. And slight pressure changes can have a significant impact on soil and crops. This is where tire pressure monitoring systems (TPMS) come in.

TPMS is a system that monitors your tires' air pressure in real-time and alerts you to any problems. This gives you the opportunity to inflate your tires before they get too low to ensure optimal performance, durability, and longevity. Knowing about tire pressure issues and remedying them quickly can help tire damage and reduce your chances of expensive downtime.

You don't have to accept ongoing tire issues if you have the right information and products. By utilizing TPMS and monitoring tire pressure, farmers can decrease tire costs and increase yield. Contact Doran to learn more: reach us by phone at 866-816-7233 or by email at INFOREQUEST@DORANMFG.COM.

Fall is approaching, and we all know what that means - it’s budgeting time for your fleet. If you haven't finalized your 2023 budget yet, you've got a lot to consider, from the cost of tires and diesel fuel to payroll and other expenses. But have you thought about including tire pressure monitoring systems (TPMS) in your 2023 budget?

TPMS can save your truck fleet money in the long run by significantly reducing your overall costs, enhancing fleet safety, and more. In this article, we'll discuss why any fleet manager would be remiss in not including them in their budget. And if you've already got a budget in place, we'll show you how investing in TPMS can help lower your overall costs.

Investing in TPMS is a smart decision for any fleet operation interested in saving money and improving safety. With so many benefits, it's hard to justify not including TPMS in your budget. If you're not using TPMS in your fleet, now is the time to start. It's necessary if you want to stay competitive, save money, and keep your equipment on the road.

As a fleet manager or owner, you're always looking for ways to save money.

A tire pressure monitoring system can reduce expenses and increase profits in several ways. Here’s how:

There are few things more important to your fleet than time. The less time your drivers have to spend on manual tire pressure checks during pre-trip & post-trip inspections, the more revenue you’ll generate. That’s why TPMS is a necessity!

A tire pressure monitoring system can reduce your drivers’ chances of getting into accidents or having blowouts, which reduce efficiency & increase costs.. The real-time information TPMS provides enables drivers to quickly identify and fix small issues before they become time-wasting dilemmas.

In addition, TPMS can help you avoid the hassle and expense of repeated repairs for damaged tires. This will save your fleet a lot of time - time that can be used to bring in more revenue.

When your truck tires aren't inflated properly, it causes premature wear. You can avoid this by having your drivers frequently check and inflate the tires, but it’s not always practical or possible to do so. TPMS takes the guesswork out of tire maintenance by constantly monitoring the pressure in your tires and alerting you when they need to be inflated. With automatic tire pressure monitoring, you’ll also save money on tire maintenance and replacement costs.

Some truck fleet managers and supervisors overlook the importance of keeping their tires’ air pressure at an optimal level, but it’s essential for safe hauling. Underinflated tires can lead to several problems, including:

All of this results in an increased risk of blowouts and accidents.

A tire pressure monitoring system (TPMS) can help to prevent these problems by constantly monitoring the pressure in your tires and alerting you when it falls below recommended levels. TPMS not only makes transporting freight safer for everyone on the road, but it also ensures that your trucks remain on the road (instead of on the side of it).

Doran Manufacturing offers a wide variety of TPMS solutions for fleet operations of all sizes - from owner-operators to small fleets to large international companies.

Doran 360™ TPMS:

Our TPMS feature several alert settings to help keep your tires at optimal pressure levels, protect against rapid deflation events, and guard against high tire temperatures.

Choose from the following models:

Before you finalize your 2023 budget, contact Doran at 866-816-7233 or request information at INFOREQUEST@DORANMFG.COM to discuss the financial savings of TPMS for your fleet. And if your 2023 budget is in place without TPMS on trucks, we encourage you to analyze your tire costs and consider leveraging technology to lower them. Your bottom line will be better for it.

Peak trucking season is now underway, and it will continue until mid-November. During this time, freight volume is at its peak, with a substantial number of trucks on the road, hauling high-demand items like school supplies and gifts for the upcoming holidays.

Fleet managers, supervisors, and drivers who prepare for the peak will be able to avoid substantial losses due to unnecessary downtime and roadside hazards.

Real-time monitoring of driver behavior and vehicle safety keeps everyone’s focus on successful hauls during the busy hauling season.

Both individual owner-operators and fleet executives should consider adding tire pressure monitoring systems (TPMS) to all their trucks. These systems help avoid unnecessary costs associated with tire replacement, lower fuel expenses, and assist owners with real-time data in order to keep their trucks moving all season.

Doran 360 TM TPMS is an innovative system that continually monitors your tires' condition and alerts you to tire pressure and temperature issues. This equates to numerous benefits for your fleet, including:

Ensuring drivers understand the importance of safety protocols and are following them consistently. Drivers should be familiar with the company's safety policies and procedures as well as local, state, and federal trucking regulations.

Trucking safety is of the utmost importance at a time when more vehicles are on the road and loads are often heavier. Drivers need to be aware of their surroundings and know how to react to potential road hazards and situations.

Minding the weather is also crucial for driver safety and ensuring their load arrives on schedule. Drivers should regularly check the weather forecast and plan their routes accordingly. They should also be aware of the signs of inclement weather and know when to pull over and wait out the storm.

Reviewing safety procedures and protocols will ensure that all drivers understand the expectations.

A certain amount of wear-and-tear is expected during normal fleet operation. But, it can quickly multiply during peak season when trucks are on the road for extended periods.

As time is more valuable than ever, utilizing TPMS to decrease time spent on pre and post trip safety checks is beneficial.

Doran’s 360SL SmartLink ™ TPMS is designed for tractor and trailer drop and hook applications. With continuous monitoring of tire pressure, drivers can keep their focus on the road. The in-cab display shows real-time data at the press of a button. Built in alerts provide warnings for high temperatures and pressure changes.

Additional safety precautions should include ensuring seasonal maintenance occurs before hitting the road. Checking batteries, filters, lights, brakes and other major components can limit costly repairs, unexpected downtime, and dangerous accidents.

We’d love to talk to you about solutions to keep your fleet safe and moving forward during the busiest time of the hauling season.